Plastic Extrusion is used in a Wide Range of Industries and Applications

Plastic extrusion is a manufacturing

process used to create objects with a fixed cross-sectional profile. It

involves pushing raw plastic material through a heated barrel, and then forcing

it through a die to form the desired shape. Here's a breakdown of the process:

Raw Material Preparation: Plastic pellets or granules are fed into a

hopper. The material can be virgin resin or recycled plastic.

Melting: The plastic material is fed into an extruder, which consists of a

rotating screw inside a heated barrel. As the screw turns, it applies heat and

pressure to melt the plastic.

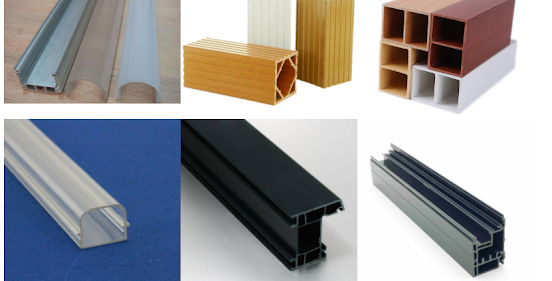

Extrusion: Once melted, the plastic is forced through a die, which determines the

shape and size of the final product. The die is typically custom-made to

produce specific profiles such as tubes, pipes, rods, or sheets.

Cooling: After exiting the die, the plastic is cooled using air or water to

solidify its shape. Cooling is crucial to maintain the desired dimensions and

structural integrity of the product.

Cutting and Finishing: Once cooled, the extruded plastic is cut to the desired length, and any additional finishing processes, such as surface treatment or printing, may be applied.

Plastic extrusion is widely used in various industries, including construction, automotive, packaging, and consumer goods, due to its versatility, cost-effectiveness, and ability to produce complex shapes with high precision.

Follow our Facebook and Twitter for more information about our product.

Comments

Post a Comment