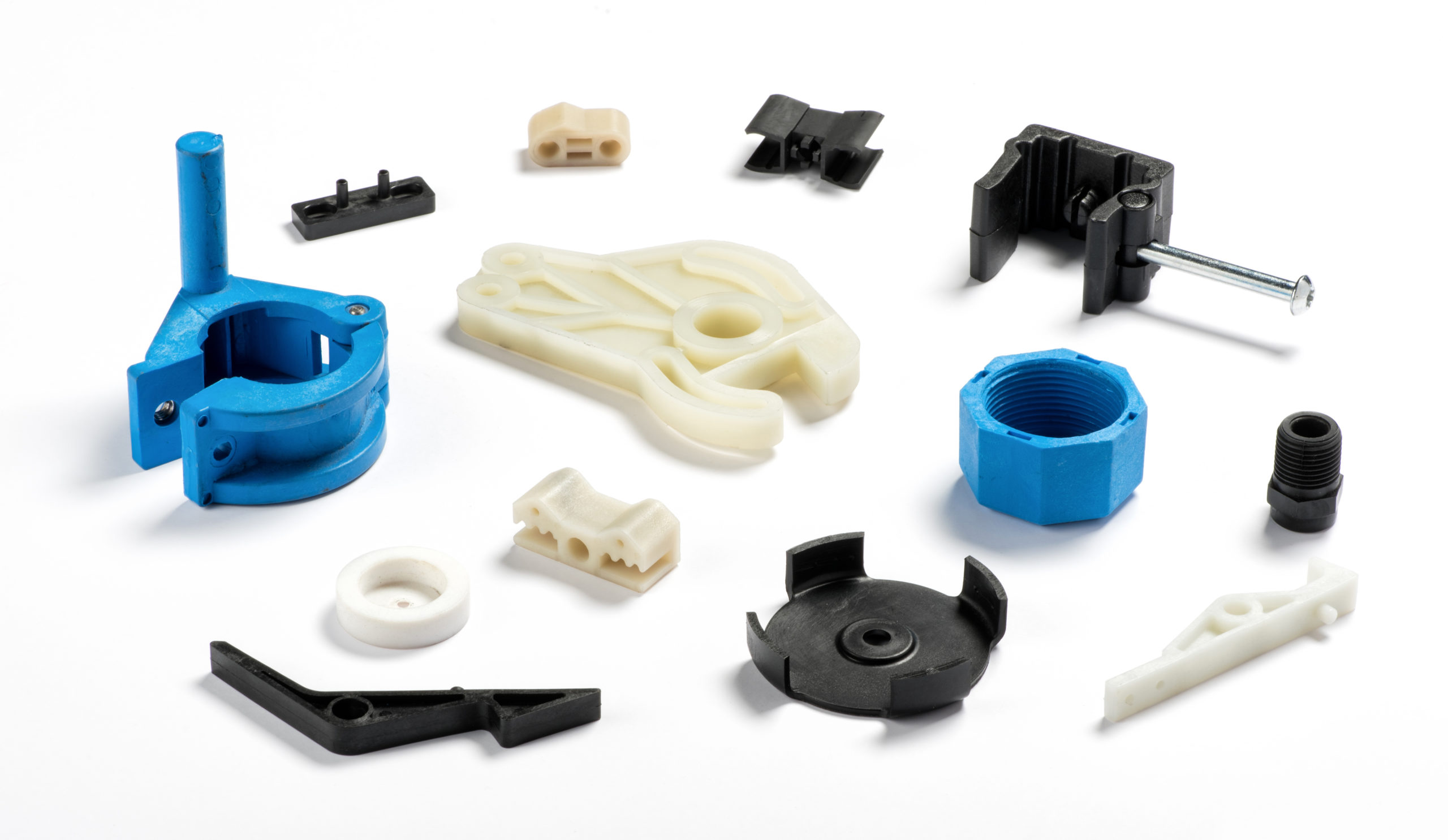

The Plastic Injection Molding Basics

The plastic injection molding process

begins with generating the product design, followed by tooling a mold to fit

the product design, melting the plastic resin pellets, and injecting the molten

pellets into the mold using pressure.

Steps

Designing the Product

Designers build

a part using fundamental design rules related to the injection molding method.

Create a Tooling Mold to Fit the Product Design

Highly trained

machinists and toolmakers use the product design to create a tooling mold for

the injection molding machine. A tooling mold, also known as a tool, is the

heart and soul of an injection molding machine. They are meticulously built to

house the negative cavity for the product design as well as extra features

including sprues, runners, gates, vents, ejector systems, cooling channels, and

moving components. Tooling molds are constructed from steel and aluminum grades

that can survive tens of thousands of heating and cooling cycles. Mold

manufacturing can take up to 20 weeks to complete, including fabrication and

approval, making it the most time-consuming phase of injection molding. It is

also the most expensive component of Plastic Injection Process, and once

created, a tooling mold cannot be significantly altered without incurring

additional expenditures.

Melt the plastic resin pellets

After obtaining

the final mold, operators place it into the injection molding machine, which

shuts and begins the injection molding cycle. Plastic pellets are put into both

the hopper and the barrel. The reciprocating screw is dragged back, allowing

materials to pass through the area between the screw and the barrel. The screw

then plunges forward, pushing the material deeper down the barrel and closer to

the heater bands, where it melts into molten plastic. The melting temperature

is maintained at the material requirements so that no deterioration happens in

the barrel or the mold itself.

Using pressure to feed the molten pellets into the mould

The reciprocating screw pushes the molten plastic through the nozzle, which is in a depression in the mold called a mold sprue bushing. The moving platen pressure compresses the mold and nozzle firmly, preventing any plastic from escaping. This Plastic Injection technique pressurizes the melted plastic, allowing it to enter all sections of the mold cavity while displacing cavity air through the mold vents.

Comments

Post a Comment